Top 10 Benefits of Using a Cable Loom for Your Projects?

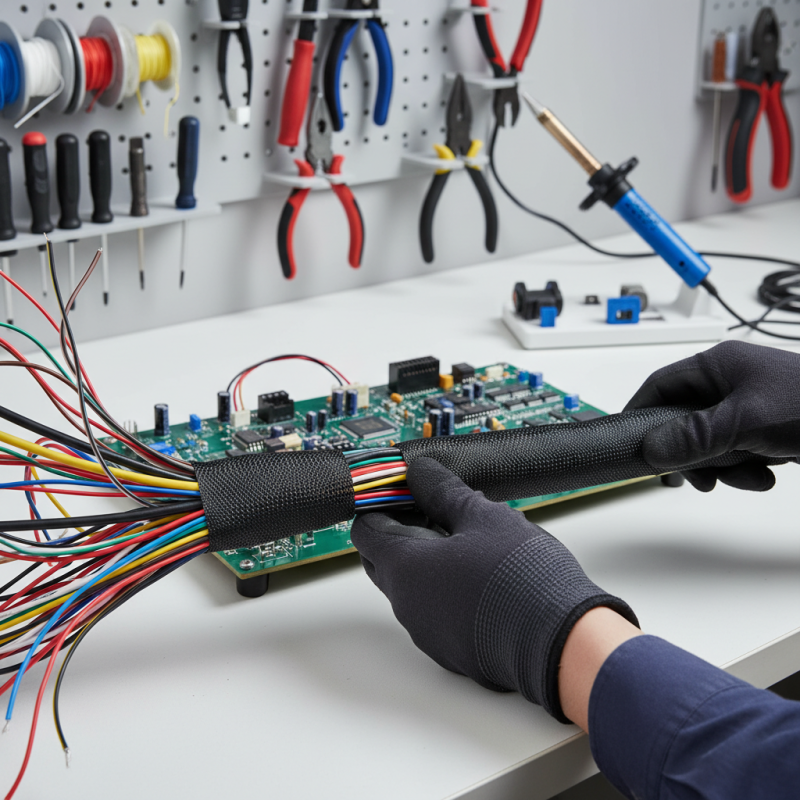

In today's fast-paced world, efficient organization is vital. A cable loom offers numerous advantages for managing wiring and cables effectively. This simple tool minimizes clutter and enhances your project's aesthetics. When wires are neatly bundled, you can focus on functionality.

Using a cable loom can improve safety, reducing the risk of tangled wires. It also helps in troubleshooting issues by providing clear visibility of connections. A well-organized setup is not only visually appealing but also practical. It can lead to quicker repairs and seamless updates.

However, not everyone understands how to use a cable loom effectively. Poorly executed techniques can lead to additional issues and frustration. Taking the time to learn the correct methods can make a significant difference in your projects. Embrace this tool to elevate your work.

Benefits of Enhanced Organization with Cable Looms

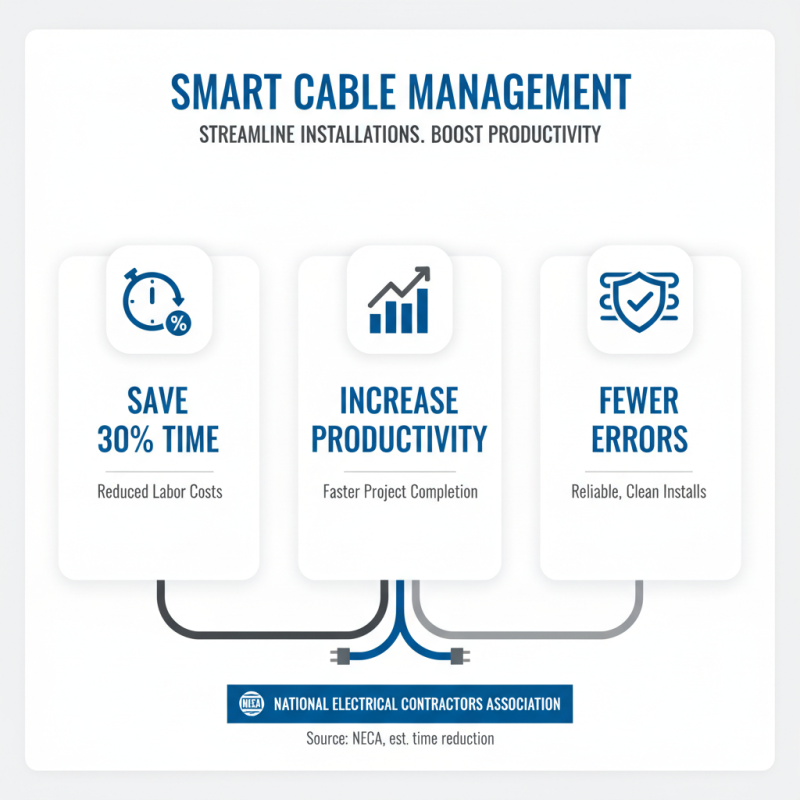

Cable looms offer significant benefits in organizing and managing wires in any project. Enhanced organization is one of the main advantages. A well-arranged cable loom minimizes clutter, which can reduce the risk of errors. Reports indicate that organized wiring can cut down installation time by as much as 30%. This efficiency is crucial in both home and industrial settings.

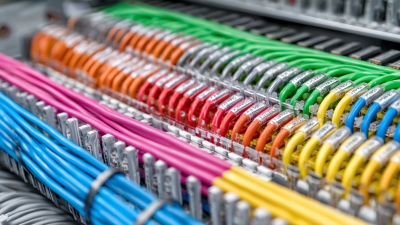

Without a cable loom, finding the right cable can be a hassle. An overwhelming mix of cords may lead to confusion and mistakes. A tidy cable loom helps track specific wires quickly. Moreover, it promotes safety by reducing tripping hazards associated with loose cables.

Tips: Label each cable clearly. Simple labels can save time when troubleshooting later. Regular audits of your cable organization can uncover areas needing improvement. Don't underestimate the value of revisiting your methods. Small adjustments can greatly enhance your cable management system. Keeping things organized not only looks professional but helps you work more effectively.

Improved Safety and Reduced Hazard Risks Using Cable Looms

Cable looms offer significant advantages when it comes to safety. They organize wires, preventing tangling and confusion. This organization reduces the chance of accidental disconnections. Clear identification of each wire improves overall safety during maintenance. A well-organized loom is easier to troubleshoot, saving time and effort.

Another benefit is the reduction of hazard risks. Exposed wires can create short circuits or ground faults. By using cable looms, these risks are minimized. The protective design shields wires from physical damage. It keeps cables out of harm's way in tight spaces. Furthermore, cable looms can often be color-coded for easy identification. This reduces the likelihood of human error during installation or repairs.

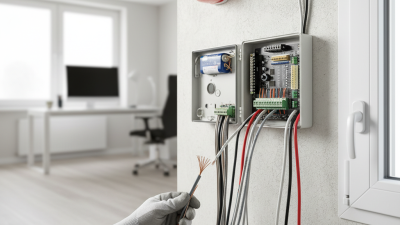

However, not all cable looms suit every project. Choosing the right type requires reflection and careful planning. Some may find standard looms too bulky for compact spaces. Others may experience difficulties during installation. Consider the specific needs of your project. This ensures optimal performance and safety. Properly assessing these factors can lead to better results and a safer working environment.

Increased Durability and Protection for Wires in Various Projects

Cable looms offer substantial benefits for wiring projects. They enhance the durability and protection of wires, which is critical in various environments. According to the International Electrotechnical Commission, improper wire management can lead to up to 30% of equipment failures. A well-structured cable loom can significantly reduce these risks.

Using cable looms also provides better strain relief. This feature prevents damage from vibration and movement, particularly in automotive and industrial applications. Reports indicate that nearly 40% of electrical issues in vehicles come from cable wear. Additionally, looms can keep wires organized, which simplifies maintenance. This organization can save time when troubleshooting or upgrading systems.

However, some projects may overlook the importance of quality materials in looms. Using subpar components can lead to premature wear, ultimately negating their protective benefits. This reflects the need for mindful selection in project management. Think about your specific requirements and environmental factors before deciding. Balancing cost and quality remains a challenge for many.

Top 10 Benefits of Using a Cable Loom for Your Projects

| Benefit | Description |

|---|---|

| Increased Durability | Cable looms provide additional protection against wear and tear, extending the lifespan of your wiring. |

| Improved Organization | Cable looms help keep wires neat and organized, making projects easier to manage. |

| Enhanced Safety | By bundling cables, looms reduce the risk of electrical hazards and short circuits. |

| Temperature Resistance | Many cable looms are made from materials that can withstand extreme temperatures. |

| Ease of Installation | Cable looms simplify the installation process by allowing for grouped wires. |

| Aesthetic Appeal | Using cable looms can improve the visual appearance of your projects by hiding unattractive wires. |

| Cost-Effective | By protecting wires, looms can reduce replacement costs due to damage. |

| Flexibility | Cable looms can accommodate a variety of wire thicknesses and types. |

| Water Resistance | Many looms provide protection against moisture, important for outdoor or humid environments. |

| Shock Absorption | Cable looms can absorb shocks and vibrations, protecting the internal wires. |

Streamlined Installation Processes with the Use of Cable Looms

Using cable looms in your projects can significantly streamline the installation process. According to the National Electrical Contractors Association, efficient cable management can reduce installation time by up to 30%. This not only minimizes labor costs but also increases productivity on job sites. When cables are neatly organized, the chances of errors are reduced, leading to fewer revisions and corrections. This is particularly crucial in complex installations where time is often a resource in short supply.

A well-structured cable loom also enhances safety. By keeping cables bundled together, the risk of accidental damage or tripping hazards is greatly reduced. Studies suggest that 25% of workplace accidents are linked to poor cable management. A clean, organized workspace not only protects workers but also contributes to better overall project quality. However, implementing cable looms requires careful planning. Sometimes, finding the right size or type of loom can be challenging. It’s essential to choose looms that provide adequate support and flexibility for your specific needs.

The upfront investment in quality cable looms can be daunting for some. Yet, many professionals see this as a necessary step for long-term success. The short-term costs might seem high, but the long-term benefits often outweigh them. It’s important to evaluate your project needs and consider the role of proper cable management in achieving your goals. The balance between cost and efficiency is a constant challenge in any project.

Cost-Effectiveness and Long-Term Savings from Utilizing Cable Looms

Using a cable loom in your projects can lead to significant cost-effectiveness. Organizing cables reduces wear and tear, extending their lifespan. This means fewer replacements over time. If cables are neatly arranged, they’re less likely to suffer damage. You won't need to spend on constant repairs.

Tip: Always choose quality materials for your cable loom. While it may seem like a larger upfront cost, it pays off in the long run. Cheap options can lead to problems and additional expenses later.

Investing in a cable loom could also enhance safety. A tangled mess can create hazards. With a well-organized setup, you lower the risk of accidents, which can be costly. Sometimes, overlooked accidents can lead to significant losses.

Tip: Regularly check your cable arrangements to ensure everything is secure. A small effort now can prevent big headaches later. Don't just assume everything is fine; do a quick visual inspection frequently. It's a simple way to maintain safety and save money.

Related Posts

-

Understanding Cable Looms: The Essential Guide to Choosing the Right Wiring Solution for Your Projects

-

10 Essential Tips for Organizing Your Cable Loom Like a Pro

-

2025 How to Choose the Best Multi Conductor Cable for Your Electrical Projects

-

Understanding the Essentials of Wiring Looms: A Guide to Simplifying Your Projects

-

What are Wire Zip Ties and How to Choose the Right One for Your Project

-

What is Alarm Cable? Understanding Types, Uses, and Installation Tips