2026 How to Choose the Right Cable Tray Wire for Your Electrical Projects?

Choosing the right cable tray wire for electrical projects can significantly impact performance and safety. According to a comprehensive industry report by Global Market Insights, the cable management systems market is projected to reach $11 billion by 2026. This growth underscores the importance of understanding the nuances of cable tray wire selection.

“Selecting the correct cable tray wire is crucial for the efficiency of electrical systems,” says industry expert John Evans, who has over 20 years of experience in electrical engineering. Many projects fail to prioritize cable tray wire choice, which can lead to long-term complications and unforeseen costs.

Factors such as material type, wire gauge, and environmental conditions play pivotal roles in decision-making. With varying standards, it’s challenging to navigate the multitude of options available. Proper research and guidance can prevent costly mistakes. Choosing wisely can improve safety and enhance system longevity.

Understanding the Different Types of Cable Tray Wires Available

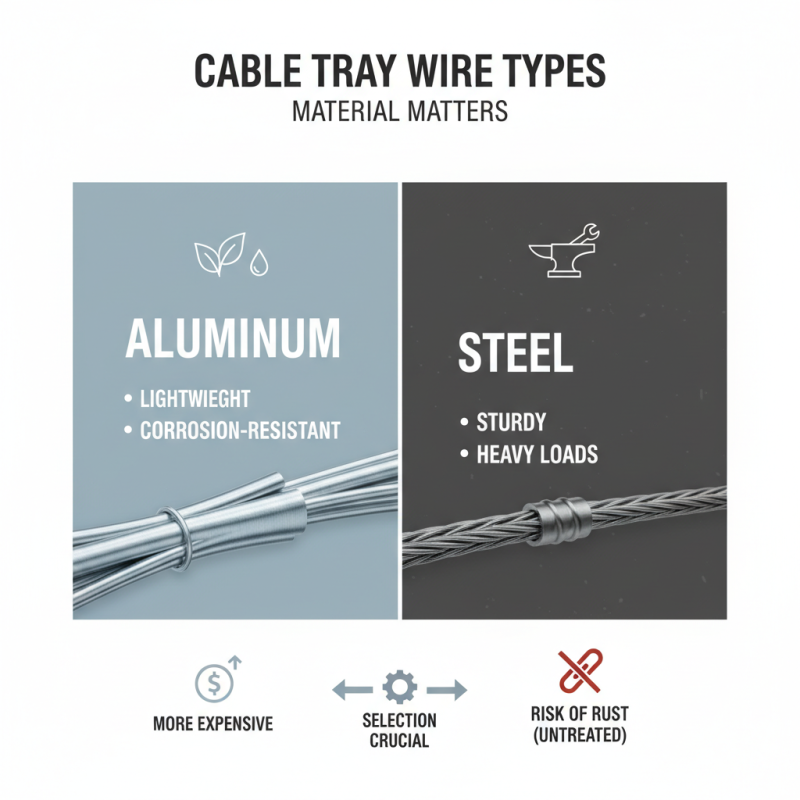

When selecting cable tray wire for electrical projects, understanding available types is crucial. Different materials have distinct characteristics. For instance, aluminum wires are lightweight and resistant to corrosion. However, they can be more expensive. Steel wires are sturdy and can support heavier loads, but they are susceptible to rust without proper treatment.

Another option is PVC-coated wire. This type is ideal for environments that require extra protection. Its coating helps guard against moisture. However, consider the cost, as it may be higher than bare wires. Then there's the option of fiberglass. It’s lightweight and non-conductive. But, is it suitable for your specific project needs?

Choosing the right wire isn't just about cost. Think about your project's environment and safety requirements. You may need to revisit your initial choice. Sometimes, what seemed perfect could hinder performance later. Balancing functionality with budget is key. Don’t rush the decision; take time to reflect on each type's benefits and drawbacks.

Key Factors to Consider When Selecting Cable Tray Wires

When selecting cable tray wires for your electrical projects, several key factors come into play. The wire gauge is critical. Thicker wires can carry more current but are also heavier and may require stronger support. Understanding the ampacity is essential for safety. Choosing the right gauge ensures you won’t experience overheating.

Next, consider the environment where the cables will be installed. Will it be indoors or outdoors? Harsh conditions require durable materials. Finally, think about the wire insulation type. Different insulations protect against moisture, heat, and chemical exposure. Each choice impacts performance and longevity.

Some project managers overlook these details. They assume one size fits all, which can lead to issues down the line. Evaluate the specific needs of your installation. Too often, people find out the hard way that what seemed good enough was, in fact, insufficient. A deeper understanding of these factors will help avoid costly mistakes.

Evaluating Electrical Load Capacity for Your Projects

When planning electrical projects, evaluating the load capacity of your cable tray is crucial. This affects safety and efficiency. Each cable type has different load requirements. It's important to understand these needs before making a choice. Focus on the wire gauge and insulation type to ensure compatibility.

Consider the size of the tray. A tray that’s too small can cause overheating. Overloading can damage cables and lead to failures. Pay attention to cable arrangement as well. Bundled cables have higher heat retention. This can further impact the load capacity. Always double-check calculations. Mistakes can be costly.

Don’t overlook environmental factors. Humidity and temperature affect performance. Cables may expand or contract with heat. It's essential to review installation conditions thoroughly. Adjusting for unexpected changes is part of project management. Regularly reassessing load capacities can lead to better choices and safer systems, ensuring long-term functionality.

Electrical Load Capacity for Different Cable Tray Types

This chart illustrates the load capacity (in amps) of various types of cable trays. Understanding these capacities is crucial when selecting the right tray for electrical projects, especially in ensuring safety and efficiency.

Assessing Environmental Conditions for Cable Tray Wire Selection

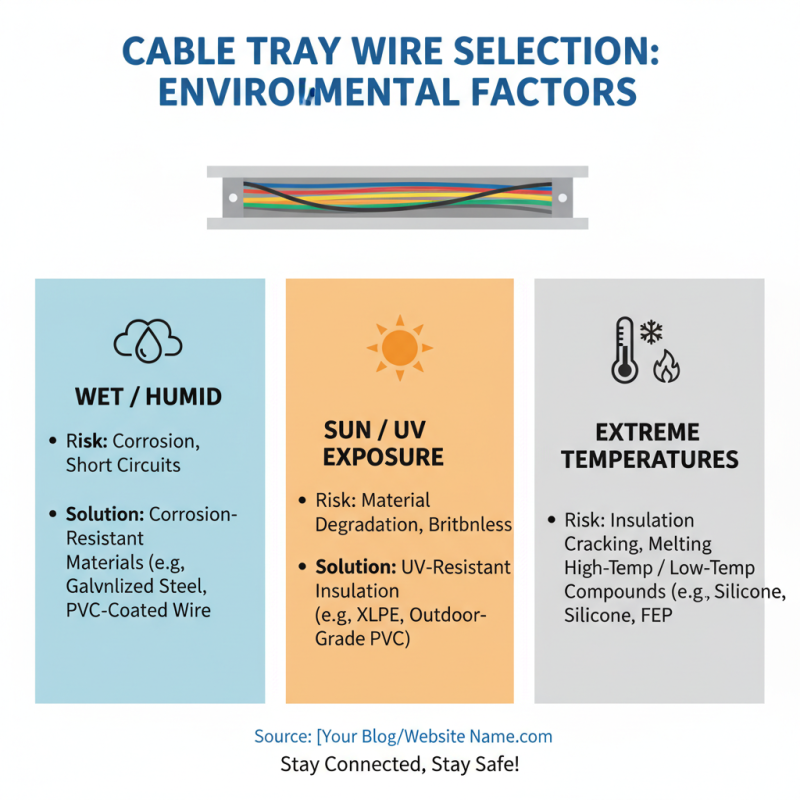

When selecting cable tray wire for electrical projects, assessing environmental conditions is vital. Different environments impact the wire's durability and effectiveness. For example, wet or humid areas may require corrosion-resistant materials. Meanwhile, exposure to sunlight and extreme temperatures can degrade certain wire types.

**Tips for Selection:** Consider the local climate. If there's high humidity, opt for wires that resist corrosion. For areas with heavy sunlight, choose UV-resistant materials. These factors will prolong the lifespan of your installation.

Also, think about the physical surroundings. Wire insulation must endure potential abrasions. If it’s in a busy area, abrasion-resistant materials could be essential. Don’t overlook potential vibrations or mechanical stresses as well. The cable tray should accommodate these to prevent future issues.

One should often reflect on the initial choices. Did you fully understand the environmental challenges? It’s an ongoing learning process. Reassessing previous selections may yield better, more practical outcomes. Stay informed and adapt your choices over time for lasting results.

Best Practices for Installing Cable Tray Wires Safely and Effectively

When installing cable tray wires, safety and effectiveness are paramount. According to industry reports, improper installation can lead to cable damage or electrical failures. Reports indicate that 30% of electrical system failures stem from inadequate cable management. Choosing the right route for the cable tray is essential. Every twist and turn can impact the wire’s performance.

The national standards recommend installing trays at least 12 inches from walls. This spacing helps prevent overheating and allows for air circulation. Remember, crowded trays can create hotspots, risking insulation integrity. Use adequate support brackets. They minimize sagging and maintain proper wire separation. A clear layout, possibly drawn on paper, can aid your installation.

Finally, do not overlook load ratings. Exceeding these can cause catastrophic failures. Reports show that overloading cables is a common mistake that can lead to injury. Regular inspection during the installation process is critical. Never rush through it. Continuous reflection on your methods can highlight hidden errors. Safety cannot take a backseat in electrical projects.

Related Posts

-

Why Wire Cable Tray Solutions Are Essential for Modern Electrical Systems

-

10 Essential Tips for Using THHN Wire in Your Electrical Projects

-

Mastering Cable Pulling Tools: Essential Techniques for Efficient Installation and Maintenance

-

Top 5 Benefits of Using High-Quality Cable Harnesses for Your Projects

-

Top 10 Benefits of Using a Cable Loom for Your Projects?

-

How to Use a Wire Snake for Effective Clog Removal in Your Plumbing System