10 Essential Tips for Using THHN Wire in Your Electrical Projects

When undertaking electrical projects, the choice of wiring is crucial for ensuring safety and efficiency. One of the most popular options among electricians and DIY enthusiasts is THHN wire, known for its durability and versatility. This type of wire is primarily used in residential and commercial applications, offering excellent resistance to heat and moisture, making it suitable for both indoor and outdoor wiring tasks. Understanding the proper use of THHN wire can significantly impact the success of your electrical installations, as improper handling and installation can lead to unforeseen hazards.

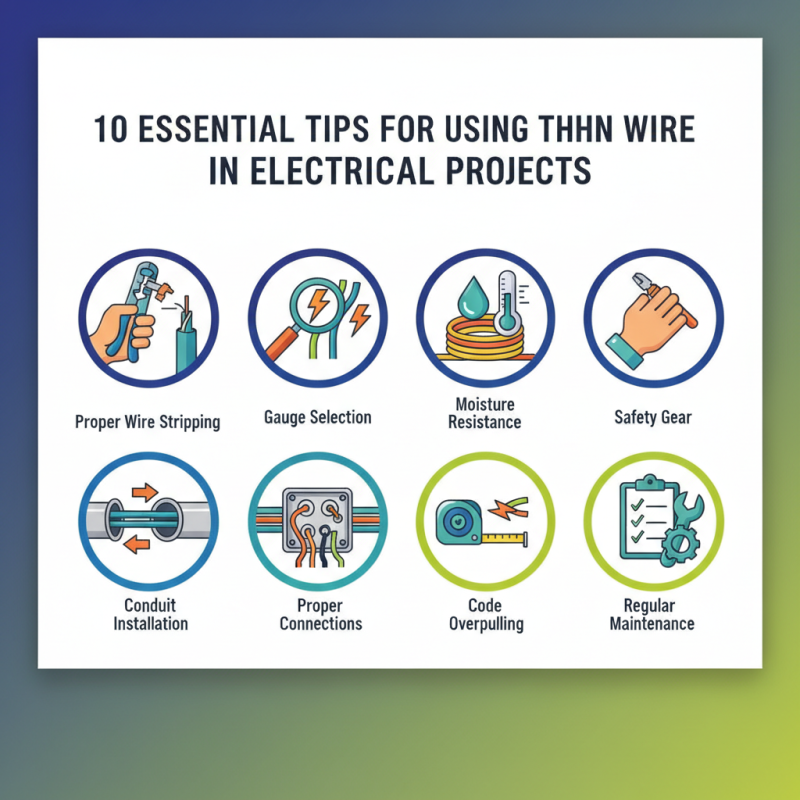

In this guide, we will explore ten essential tips for effectively using THHN wire in your electrical projects. From selecting the right gauge for your specific needs to proper installation techniques, each tip is designed to enhance your knowledge and improve your skill set. By following these guidelines, you can ensure that your electrical systems not only function optimally but also comply with safety regulations. With the proper understanding and application of THHN wire, you can confidently tackle a variety of electrical challenges, enhancing both the performance and longevity of your projects.

Understanding THHN Wire: Specifications and Types

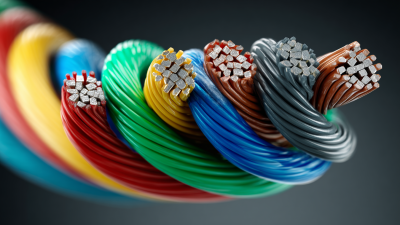

THHN wire, or Thermoplastic High Heat-resistant Nylon-coated wire, is a versatile choice for various electrical applications. It is primarily made of copper or aluminum conductors, covered with a thermoplastic insulation that can withstand high temperatures—up to 90 degrees Celsius in dry locations. This wire is often used for building, commercial, and industrial applications due to its reliability and durability. Additionally, THHN wire is available in different gauges, allowing for flexibility depending on the electrical load requirements of your project.

When selecting THHN wire, it's essential to consider the specific types available. THHN can come in solid or stranded forms, with solid wire being suitable for permanent installations, while stranded wire provides more flexibility for movement and bending, making it ideal for temporary setups or spaces where the wire needs to maneuver around obstacles. Furthermore, THHN wire typically comes in a variety of colors, enabling easy identification of different circuits, which is crucial for safety and organization in any electrical project. Understanding these specifications and types ensures that you choose the right wire for your specific needs, leading to safer and more effective electrical installations.

Choosing the Right Gauge for Your Electrical Project

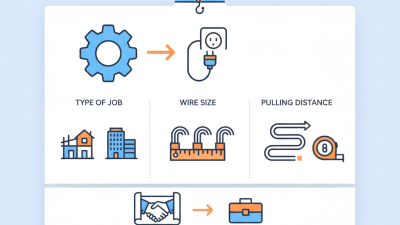

When it comes to electrical projects, choosing the right gauge of THHN wire is crucial for ensuring safety and efficiency. The gauge refers to the wire's diameter, which affects its current-carrying capacity. For residential applications, a larger gauge wire is generally suitable for higher power requirements, while a smaller gauge can be used for lighter loads. It's essential to consider the specific demands of your project, including the appliances or devices that will be connected.

One tip to keep in mind is to consult the National Electrical Code (NEC) guidelines for wire gauge requirements. This can help you understand the maximum amperage your chosen wire can handle safely. Additionally, consider the length of the wire run, as longer distances may require a larger gauge to prevent voltage drop. For instance, if you're installing wiring for lighting or outlets far from the main panel, opting for a thicker wire can help maintain performance.

Another important factor is the environment in which the wire will be used. THHN wire is rated for various conditions, whether installed in conduit or exposed to outdoor elements. Ensure that your chosen gauge and insulation type align with the environmental factors to avoid future complications. By meticulously selecting the appropriate gauge, you set a solid foundation for a safe and effective electrical project.

Proper Handling and Installation Techniques for THHN Wire

When working with THHN wire, proper handling and installation are crucial to ensure safety and efficiency in electrical projects. One of the primary considerations is the wire's temperature rating; THHN wire is rated for 90°C in dry locations, allowing it to handle high temperature environments efficiently. However, it's essential to avoid exceeding this temperature to prevent insulation breakdown. According to the National Electrical Code (NEC), ensuring that the wire is correctly rated for the intended application is vital. For example, when using THHN in conduit, it's important to account for the fill capacity to avoid overheating, which could lead to potential failures or hazards.

Furthermore, proper installation techniques can greatly enhance the durability of THHN wire. It is recommended to avoid sharp bends during wiring runs to minimize stress on the insulation and conductor. The American National Standards Institute (ANSI) suggests maintaining a minimum bend radius, typically six times the wire's diameter, to prevent damage. Additionally, securing the wire with appropriate fasteners can avoid movement that may cause wear and tear over time. Keeping these handling and installation techniques in mind not only improves the performance of electrical systems but also aligns with industry best practices, ensuring compliance with established standards and enhancing safety for end-users.

10 Essential Tips for Using THHN Wire in Your Electrical Projects

Safety Precautions When Working with THHN Wire

When working with THHN wire, safety should always be your top priority. Before starting any electrical project, ensure you are wearing appropriate personal protective equipment (PPE), such as insulated gloves and safety goggles. These precautions help protect you from potential electrical shocks and injuries caused by flying debris or accidental contact with live wires. Additionally, make sure that the work area is well-lit and organized to minimize the risk of tripping or other accidents.

It is crucial to verify that the power supply is turned off before handling THHN wire. Use a multimeter to confirm that there is no voltage present. This step is essential as it guards against electrocution. Always work with a partner when possible, as having someone nearby can provide immediate assistance in case of an emergency.

Lastly, familiarize yourself with local electrical codes and practices, as they provide guidelines that can enhance safety and ensure that your project complies with legal standards. By following these safety precautions, you’ll create a safer environment for yourself and others while using THHN wire in your electrical projects.

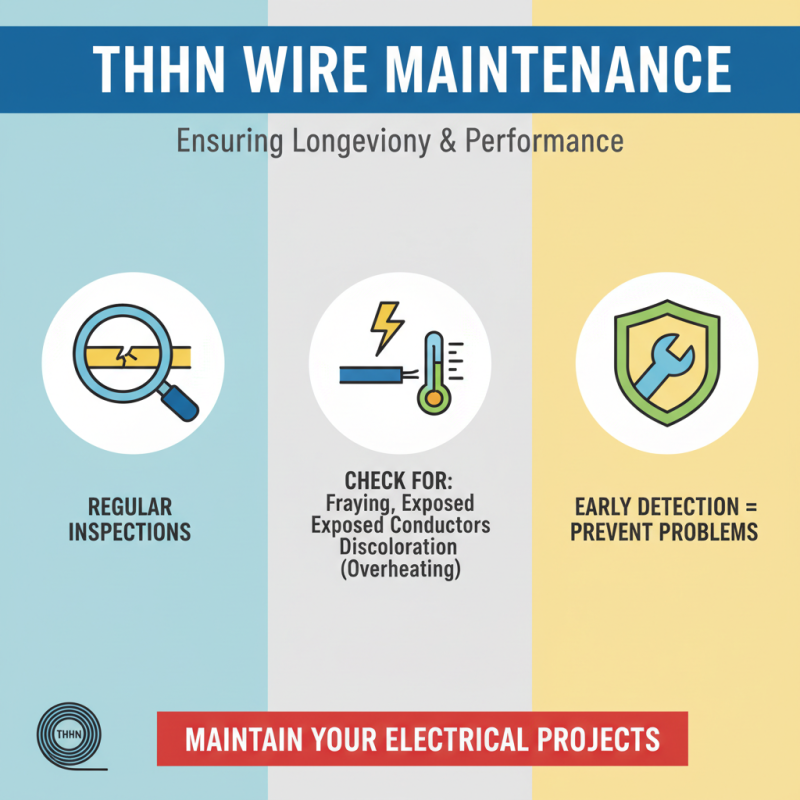

Maintenance Tips for Ensuring Longevity of THHN Wire Installations

When using THHN wire in electrical projects, proper maintenance is essential to ensure its longevity and performance. Regular inspections should be conducted to check for any signs of wear or damage. Look for fraying insulation, exposed conductors, or any discoloration that may indicate overheating. Early detection of these issues can prevent more significant problems down the line.

Another key tip is to keep THHN wire from direct sunlight or extreme temperatures. While THHN wire is designed to withstand various conditions, prolonged exposure to UV rays or excessive heat can degrade its insulation. Use protective conduits or covers when running wire through areas exposed to harsh environmental factors. Additionally, ensure that all connections are secure and insulated properly to reduce the risk of electrical faults.

Finally, maintaining a tidy workspace during your installation is crucial. Clutter can lead to accidental damage to the wire, so ensure that tools and materials are organized and stored properly. By following these maintenance tips, you can maximize the lifespan of your THHN wire installations and enhance the overall safety and reliability of your electrical projects.

Related Posts

-

2025's Top 5 THHN Wire Innovations: Essential Choices for Electrical Projects

-

Top 10 THHN Wire Options for Your Electrical Projects in 2023

-

2025 Top Fire Alarm Wire Trends and Industry Insights for Enhanced Safety Solutions

-

How to Choose the Best Wire Puller for Your Electrical Projects

-

How to Use Wire Ties Effectively for Organizing and Securing Items

-

2025 Top Trends in Electrical Wire: Insights from the Global Market Report