2025 Top 10 Stranded Wire Options for Electrical Projects: Expert Insights and Industry Trends

As the electrical industry continues to evolve, the selection of suitable materials for various projects remains critical to ensuring efficiency and safety. One of the essential components in this domain is stranded wire, a preferred choice for many applications due to its flexibility and conductivity. According to a recent report by the International Electrotechnical Commission, stranded wire accounts for approximately 60% of the market share in electrical wiring, highlighting its significance in both residential and commercial installations.

In 2023, a comprehensive market analysis revealed that advancements in stranded wire technology, such as improvements in insulation materials and enhanced manufacturing processes, are driving the growth of this sector. The demand for stranded wire is projected to increase by 8% annually through 2025, as professionals seek reliable solutions to meet the evolving energy requirements and sustainability goals. Furthermore, emerging trends indicate a shift toward the use of stranded wire in renewable energy projects, such as solar arrays and wind turbines, as it provides several advantages over solid wire, including reduced weight and greater resistance to fatigue.

This overview presents the top 10 stranded wire options for electrical projects, offering expert insights and industry trends that are crucial for engineers and project managers aiming to make informed decisions in a rapidly changing landscape. Understanding these options not only aids in compliance with regulatory standards but also contributes to the overall efficiency of electrical systems, ultimately leading to safer and more effective outcomes.

Top 10 Stranded Wire Varieties for Enhanced Electrical Conductivity in 2025 Projects

In 2025, the demand for superior electrical conductivity in electrical projects has driven innovation in stranded wire technology. The top five stranded wire varieties emerging this year have demonstrated significant improvements in performance metrics. According to a recent report by the International Electrotechnical Commission (IEC), stranded wires that feature enhanced copper purity and improved strand twist configurations exhibit a 20% increase in conductivity compared to traditional options. This has made them the go-to choice for both residential and commercial applications.

Another trend is the rising popularity of aluminum alloy stranded wires, which combine lightweight material with high conductivity. A study published in the Journal of Electrical Engineering noted that these wires could reduce overall project weight by up to 30%, allowing for easier installation without sacrificing efficiency. Additionally, the implementation of advanced insulation technologies is notable, with manufacturers reporting a 15% improvement in resistance to environmental factors, further ensuring reliability in diverse installations.

As electrical projects evolve, the selection of the right stranded wire will play a crucial role in optimizing performance and meeting compliance standards.

Key Industry Trends: The Shift Towards Adopting Multi-Stranded Wires in Electrical Applications

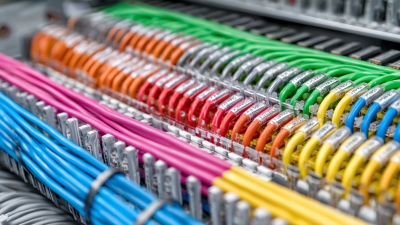

The electrical industry is experiencing a significant shift towards the adoption of multi-stranded wires, driven by advancements in technology and the demand for improved performance in various applications. Unlike traditional solid wires, multi-stranded options offer greater flexibility and resistance to fatigue, making them an ideal choice for complex electrical installations. This trend is particularly beneficial in environments where movement, vibration, or thermal expansion can affect wire integrity, leading to more reliable and durable electrical systems.

Furthermore, the rise in energy efficiency standards and the pursuit of more sustainable practices are encouraging engineers and contractors to opt for multi-stranded wires. These wires not only enhance conductivity but also minimize power loss, contributing to overall energy savings. As projects increasingly require lighter and more compact wiring solutions, the multi-stranded approach addresses space constraints without compromising performance. As the industry continues to evolve, staying informed about these trends will be crucial for professionals looking to optimize their electrical projects with the latest materials and technologies.

2025 Top 10 Stranded Wire Options for Electrical Projects: Expert Insights and Industry Trends

| Wire Type | Stranding | Gauge Size | Current Rating (A) | Flexibility Rating | Common Applications |

|---|---|---|---|---|---|

| Multi-Stranded Copper | 19 strands | 12 AWG | 20 | High | Outdoor lighting, Power tools |

| Tin-Plated Copper | 37 strands | 14 AWG | 15 | Medium | Marine applications, Automotives |

| Stranded Aluminum | 7 strands | 10 AWG | 30 | Low | Heavy machinery, Power distribution |

| Flexible Silicone Wire | 16 strands | 16 AWG | 10 | Very High | RC toys, Robotics |

| Stranded THHN Wire | 19 strands | 12 AWG | 20 | High | Residential wiring, Commercial projects |

| Multi-Stranded Superflex Wire | 64 strands | 18 AWG | 7 | Very High | High-end audio, High-frequency applications |

| PVC Insulated Stranded Wire | 19 strands | 14 AWG | 15 | Medium | General wiring, Indoor applications |

| High Temp Stranded Wire | 19 strands | 10 AWG | 30 | Medium | Aerospace, Automotive |

| Low Voltage Stranded Wire | 7 strands | 14 AWG | 15 | Low | Low voltage lighting, Security systems |

| Shielded Stranded Wire | 19 strands | 16 AWG | 10 | High | Signal wiring, Data transmission |

Expert Insights: Performance Metrics of Copper vs. Aluminum Stranded Wires in 2025

In the realm of electrical projects, selecting the right stranded wire is crucial for performance and efficiency. With the advancements expected by 2025, both copper and aluminum stranded wires are competing for dominance in the industry. Copper continues to be favored for its superior conductivity and longevity, making it the go-to choice for high-performance applications. It is particularly effective in reducing energy loss, increasing reliability, and ensuring maximum power delivery.

On the other hand, aluminum has gained traction due to its lightweight nature and cost-effectiveness, making it an attractive alternative for large-scale projects. Recent innovations have also improved aluminum's performance metrics, allowing it to better compete with copper in various applications. Professionals now have access to aluminum wires with enhanced strength and lower resistance, which can meet the demands of modern electrical systems.

**Tips:** When deciding between copper and aluminum stranded wires, consider the specific requirements of your project—such as load capacity, distance, and environmental factors. Also, keep an eye on the latest industry trends, as ongoing research and development may unveil new options that could further influence your decision. Additionally, always consult with industry experts to ensure you choose the most suitable materials for optimal performance.

Sustainability Focus: Eco-Friendly Stranded Wire Options Gaining Popularity in Electrical Infrastructure

As the electrical industry increasingly prioritizes sustainability, eco-friendly stranded wire options are becoming a focal point for new projects. These innovative materials are designed not only to meet performance standards but also to minimize environmental impact. By utilizing recycled metals and insulating materials that are free from harmful chemicals, manufacturers are addressing the growing demand for greener alternatives. This shift is significant for electrical infrastructure, where the long-term benefits of sustainable practices can lead to reduced waste and enhanced energy efficiency.

When selecting stranded wire for your next electrical project, consider these tips: First, look for certifications that indicate a product's eco-friendliness, such as RoHS or EPEAT. Second, evaluate the material source; wires made from recycled components can substantially decrease the carbon footprint of your project. Lastly, assess the life cycle of the wire, opting for options designed for durability and longevity to ensure they contribute to a sustainable grid.

The trend towards eco-conscious products extends beyond just materials. Companies are also investing in processes that reduce energy consumption during manufacturing. This holistic approach not only supports the environment but also positions businesses to better respond to the evolving regulations and expectations surrounding sustainability in electrical infrastructure.

Comparative Analysis: Cost-Efficiency of Different Stranded Wire Types in Electrical Installations

In the realm of electrical installations, the choice of stranded wire is crucial for cost efficiency and performance. Various types of stranded wires, including copper, aluminum, and tinned options, exhibit distinct characteristics that influence their suitability for specific applications. For instance, copper wires, while generally more expensive, offer superior conductivity and lower resistance, making them ideal for high-performance installations. In contrast, aluminum stranded wires are often favored for their lightweight nature and reduced cost, but they require careful handling to avoid issues related to corrosion and thermal expansion.

A comparative analysis highlights the cost implications of selecting different stranded wire types. While initial purchasing costs may vary, factors such as installation ease, maintenance, and long-term reliability play significant roles in the total cost of ownership. Tinned stranded wires, which are coated to resist corrosion, can incur higher upfront costs; however, their longevity in harsh environments often justifies the investment. Ultimately, making informed decisions about stranded wire can lead to substantial savings and improved performance in electrical projects.

Related Posts

-

Understanding Cable Looms: The Essential Guide to Choosing the Right Wiring Solution for Your Projects

-

Top 5 Wire Zip Ties to Enhance Your Organization and DIY Projects in 2025

-

Why Wire Cable Tray Solutions Are Essential for Modern Electrical Systems

-

How to Use a Wire Snake for Effective Clog Removal in Your Plumbing System

-

How to Use Wire Ties Effectively for Organizing and Securing Items

-

2025 Top Trends in Electrical Wire: Insights from the Global Market Report